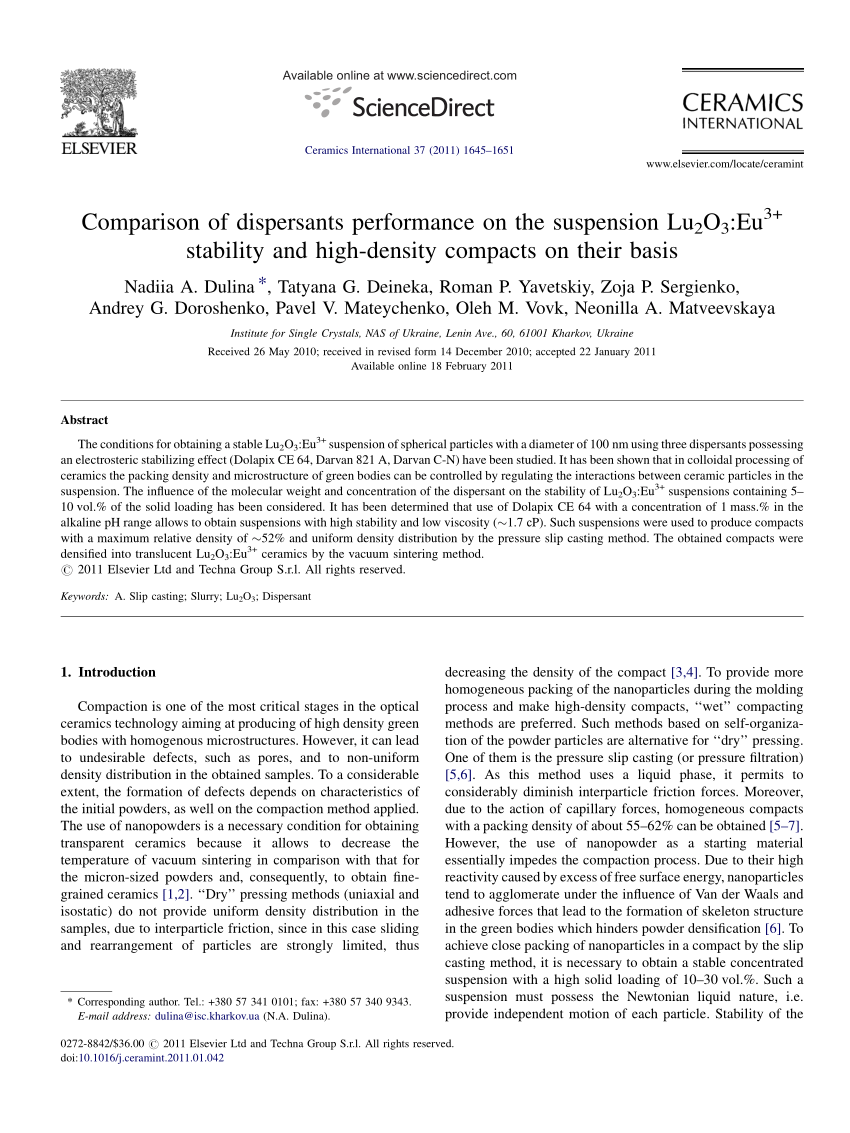

Dispersion of ceramic particles in aqueous media with surface grafted dispersant kimiyasu sato w z hu seyin yilmaz z y yuji hotta z atsuko ijuin z and koji watariz znational institute of advanced industrial science and technology aist nagoya 463 8560 japan ygebze institute of technology materials science and engineering department 41400 gebze kocaeli turkey.

Ceramic slurry dispersant.

Ammonium citrate and polyethylenimine have been.

Which dispersant do you think might be more appropriate to use as a starting point to prepare a water based slurry composed of ceramic of micron sized particles.

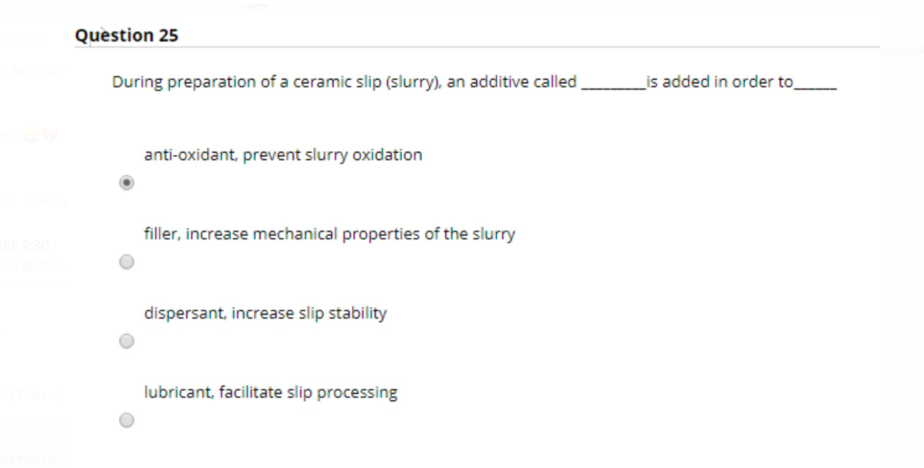

Dispersants can help to decrease viscosity and help achieve a narrow particle size distribution by reducing agglomeration.

At a high level dispersants are used in ceramic formulations to wet and disperse fine powders in media like water and for rheology control.

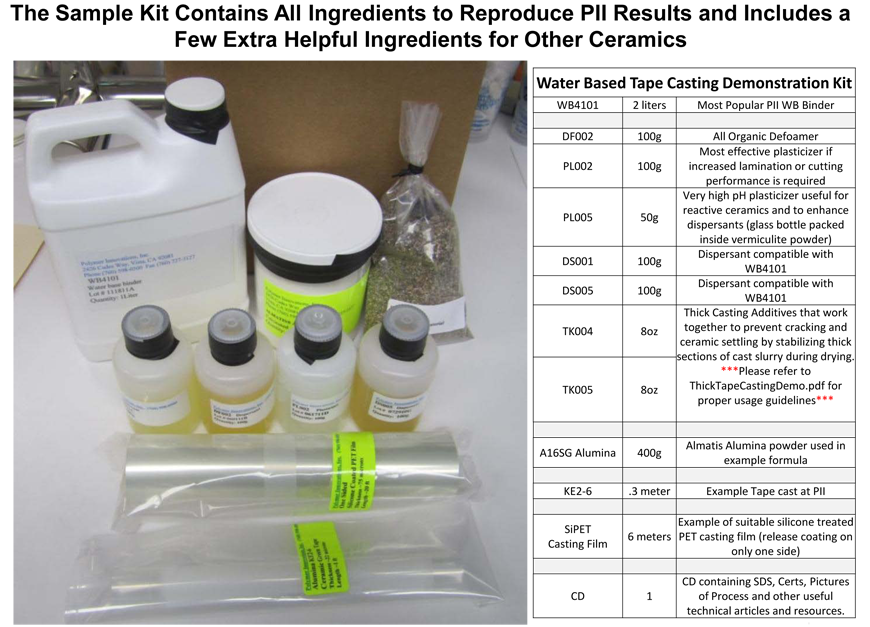

Ceramic slurry is obtained by mixing ceramic powder carrying vehicle binder and dispersant to produce uniformly dispersed ceramic slurry.

To produce ceramics with the best properties and to facilitate ball milling or spray drying a dispersant is normally added to the ceramic slurry.